For molding engineers, the main challenge lies in seeking an ideal molding configuration (structure). Facing the requirements in aspects such as product design, material selection, limitations of process conditions, and requirements for tool selection, the most difficult task for molding engineers is to achieve process optimization. The traditional approach is to use design inspiration and some advanced CAE simulation tools to identify problems before they occur; however, achieving a complete optimization of the design and process is a tough battle.

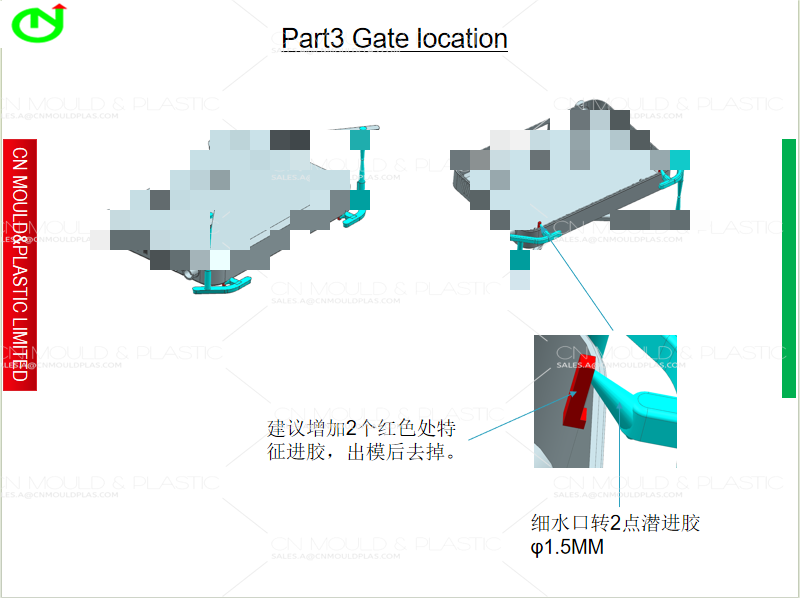

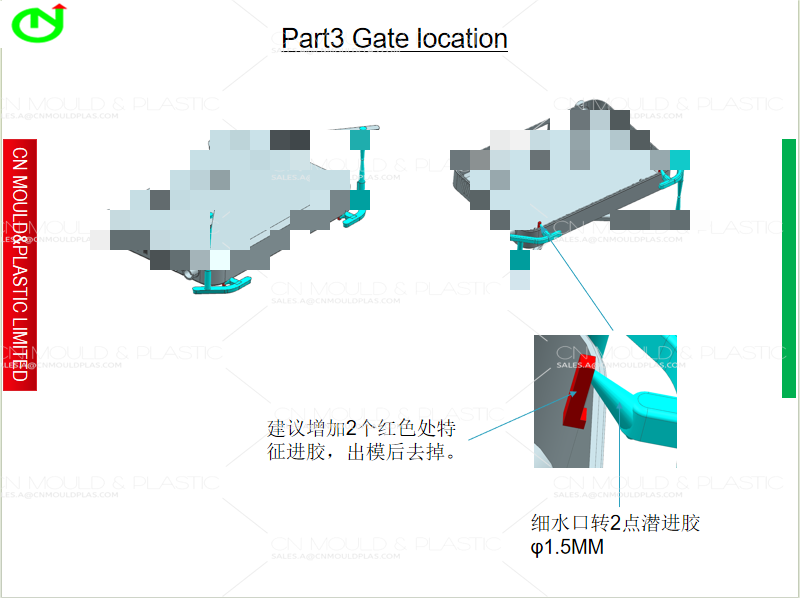

1.Gate Optimization

Some attempts have been made to automatically determine the optimal gate configuration for injection-molded parts; however, in order to determine the optimal conditions, designers must identify which parameters and measurements are the limiting process parameters. Additionally, rigorous mathematical methods must be employed to ensure the repeatability of the optimization program and to ensure a convergent solution.

The method proposed by Ye and Wang compares various methods for optimizing the gate location in injection molding. They discuss and compare a more effective genetic algorithm and simulated annealing method to explore the optimal gate location. Their technique can be applied to products with single gates and multiple gates, and aims to balance the flow path and minimize the warpage of the entire product. Although there are many specific requirements for this pioneering research, this more general method can optimize any program variables.

2.Active Process Control

With the continuous improvement of simulation technology and the increase in the accuracy of the obtained results, the next step is clearly to make the simulation results play a more active role in process control. Molders recognize that to ensure quality, a consistent optimization strategy must be implemented in both machine operation and production control. Although advanced statistical process control (SPC) has been used to troubleshoot the process, a more proactive approach is required, that is, using CAE and test feedback to directly control the process.

The basic idea of the "knowledge-based system" is to establish a system that can acquire and utilize a large amount of information and experience to improve the injection molding process. By reducing the dependence on experienced personnel, the purpose of active process control is to standardize the setup and troubleshooting processes. Some researchers have used these expert systems in some preliminary feasibility studies. Essentially, the molding conditions determined during the setup phase are used to form a reliable process window to produce qualified products. It can complete the automatic "Design of Experiments" (DOE) and correlate the CAE results with the molded products. The results generated by these DOE can provide a set of guidelines for process variables and product quality. Then the optimization program can determine a set of the most reliable process conditions for producing qualified products.

In addition, when used under the active control loop, an expert system can feedback the information from the downstream quality inspection system to modify the machine settings in order to obtain the best products. The modification of these settings is transmitted to the machine operator through the control panel, or preferably directly to the injection machine. By combining the great potential of the CAE results with the physical results obtained from the molding process, an expert system for the injection molding process can be fully realized.

Computer-aided engineering for injection molding has made breakthrough progress from its initial origin to the present. Mold design and process design, once hailed as "magic", have been firmly established on basic science, enabling the design of injection-molded products and process design to be completed through reasonable scientific laws, rather than relying solely on experience. The continuous progress and development of computer hardware and software tools make CAE suitable for the molding product industry of any specification. CAE was only used by large mold manufacturing companies in the early days, but now it has become mainstream software and is affordable and usable even for some of the smallest "family-owned" mold factories.

With the continuous growth of the demand for cost reduction, performance improvement, and cycle time shortening, CAE software is excellent in terms of yield. However, blindly believing in computer simulation should not be used to categorically replace the role of engineers. The appropriate approach is to continue using CAE to solve processing problems and help achieve the goal of designing "flawless" products. The current research focus mainly centers on continuously improving the integration among design, production, and quality. The fundamental goal of CAE in injection molding is as clear now as it was in the initial stage.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk