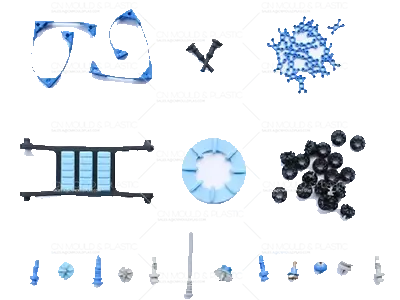

Core Fitting

Wire electrical discharge machining (WEDM) is generally adopted for the machining of mold cores.

Cores without steps: These are the simplest to machine, and high precision can be easily achieved.

Cores with steps: Their machining difficulty increases significantly. WEDM for such cores requires re-clamping, which not only increases the workload but also may lead to a decline in the dimensional accuracy of the cores.

Sometimes, for product requirements, matching cores (one in the moving mold and one in the fixed mold) can be used. To ensure accurate spatial positioning, the cores can be adjusted for height during the assembly process, and their shape should be machined as "without steps".

During mold testing, if the process cycle is long, the lower core may be pulled out together with the product—especially in the first few mold tests. Without special treatment, the risk of the core being pulled out is quite high. Therefore, following the mold testing method introduced in the "Work-Integrated Learning Content" of Task 3 may help improve this issue.

It is even better if, during mold assembly, the tail of the core can be tightly punched laterally with a center punch. If necessary, the tail of the core can be connected to the lower mold plate with screws.

Complexity of the runner inside the cavity

The melt flows in the cavity following different rules. People have used all kinds of mathematical models and formulas to describe various situations. In terms of shape, there are square columns, cylinders, squares, spheres, long strips, flat shapes, and all sorts of curved and irregular shapes. It's easy to imagine how this complexity affects the flow. This is where most difficulties in test molding come from. Sometimes, you have to ignore some minor factors and focus on the main ones.

When filling the mold, you generally want a fast filling speed to minimize temperature loss. However, this is different when the runner has sharp turns. The strong shearing effect can cause a sudden rise in local temperature. Heat-sensitive plastics will decompose due to excessive temperature, and pressure-sensitive plastics will undergo shear thinning or thickening, which immediately has a huge impact on the flow. This is also where some runner analysis software falls short.

Fast filling can also lead to "cavitation," which shows up as burn marks and silver streaks. But slow filling isn't the best option either. First, slow filling increases the temperature gradient, causing weld lines to appear or become more noticeable. Second, slow filling means that some plastics that need shear heat to aid flow won't get that help, making filling difficult. If you can find reasonable process parameters to produce qualified products, then the test molding is a success. Otherwise, mold repair is unavoidable.

Position of the vent gap

Generally, there are gaps at the core, ejector pins, etc., through which gas can escape during injection. If there's insufficient material in dead corners or at the weld lines, you should consider venting. The vent gap is usually no more than 0.05mm (it depends on the fluidity of the plastic; more fluid plastics need a smaller vent gap, and vice versa). The size of the vent gap is adjusted by increasing or decreasing its width.

The vent gap is usually placed at the end or the meeting point of the fluid flow. Sometimes, due to mold structure constraints, it can only be placed in the middle of the fluid flow path—for example, when the end of the fluid flow is a solid dead corner where a vent gap can't be machined. The size of the vent gap must be appropriate. If it's too small, the problem of insufficient material can't be solved, and in severe cases, the high-speed friction of gas at the vent gap can generate local high temperatures that "burn" the plastic. If it's too large, it increases the risk of material leakage in the future and also adds to the mold machining workload. During test molding, if the venting problem can be solved by reducing the injection speed, you should try to avoid mold repair.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk