True automation is a seamlessly integrated system where vision, gripping, movement, error-proofing, and timing work in harmony. Let’s break down what it takes to build a robust and reliable automation solution for injection molding.

First, you need to know where the parts are.

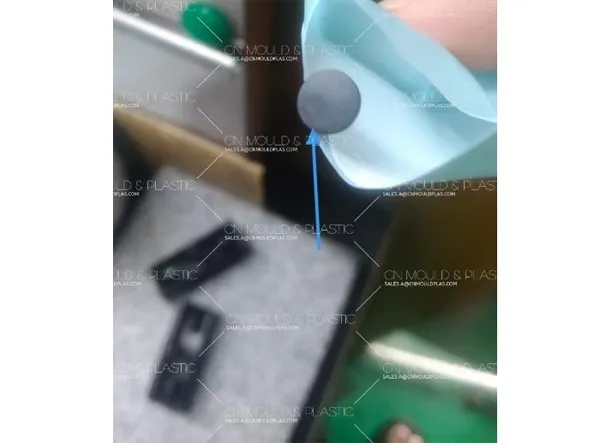

Before any action can happen, the system must “see” what it’s working with. Machine vision acts as the eyes of your automation cell. It identifies the position, orientation, and even inspects the quality of parts—such as ensuring pins or inserts are correctly placed before the robot picks them up.

Application Example: A camera positioned above an insert-loading station confirms the exact location and orientation of metal pins, allowing the robot to pick them accurately every time.

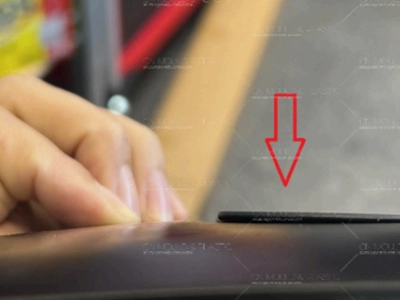

A slippery or poorly shaped gripper will fail every time.

Just like human fingers, the end-of-arm tooling (EOAT) must match the part’s geometry and material. A poorly designed gripper can drop, scratch, or misalign components—leading to downtime or scrap.

Key Consideration: Use soft grippers for delicate parts, magnetic grippers for metallic inserts, or custom-designed jaws for complex geometries. The right gripper ensures a secure and repeatable pick-and-place process.

Your fingers can’t do much without arms to move them.

Once the gripper securely holds the part, the 6-axis robot provides the flexibility to transfer it between stations—whether from the mold to a conveyor, an inspection camera, or a packaging area. Its multi-axis movement allows it to navigate tight spaces and approach from optimal angles.

Why It Shines: It handles complex paths and orientations that simpler robots cannot, making it ideal for intricate demolding or multi-step processes.

Robots don’t get tired, but they can make mistakes.

Even the best automation systems need safeguards. Error-proofing mechanisms—such as sensors that confirm part presence, force-torque sensing to detect mispicks, or vision re-checks after placement—ensure mistakes are caught before they become defects.

Example: If a part isn’t fully ejected from the mold, a proximity sensor signals the robot to wait rather than crashing into the tool.

Everything must happen at the right time—or the whole process fails.

Timing is critical in injection molding. If the robot waits too long for a signal, the molten plastic can degrade in the barrel, leading to scrap parts and wasted material. A well-integrated system uses a central controller (PLC or robot controller) to synchronize the robot, mold machine, peripherals, and alarms.

Crucial Function: The system should trigger an alarm—or even an automatic shutdown—if any station exceeds its expected cycle time.

Building a full automation cell isn’t just about buying a robot. It’s about integrating:

✅ Vision to guide actions

✅ Grippers to handle parts safely

✅ Robots to move with precision

✅ Sensors to prevent errors

✅ Timing controls to keep the cycle in sync

When these five elements work together, you get more than automation—you get a resilient, high-speed, and scrap-reducing production asset.