The quality of plastic coating isn't just closely linked to the coating process and operation itself. Things like the choice of plastic material for the parts, their structural design, the plastic molds used, the plastic molding process, and post-treatment processes also have a big impact on coating quality.

Choosing the plastic material for the parts

The higher the butadiene content in ABS plastic, the stronger the adhesion of the plating layer.coating-grade ABS plastic has a butadiene content of 22% to 24%. Tests show that the plating adhesion of coating-grade ABS resin is more than twice that of non-coating-grade ABS resin.

Structural design

If a plastic part has lots of right angles and sharp edges, those areas have internal stress, which is bad for the plating's adhesion. When you change those right angles and sharp edges to rounded transitions, the plating bonds well with the base material. On the other hand, right angles and sharp edges tend to cause too much current density at the tips during coating. This makes the plating loose and poorly bonded, and can even burn or break through the chemical pre-plating layer.

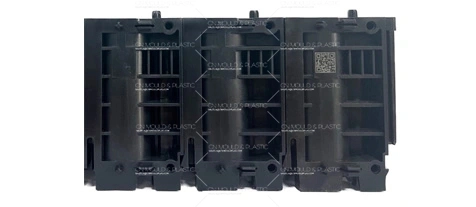

Plastic molds

If the mold cavity isn't smooth enough, the plastic part's surface won't be shiny, and that affects how shiny the plating turns out. Also, when designing plastic molds (like the gating system and ejection mechanism), you need to make sure the internal stress of the part to be plated is as low as possible. For parts with sharp corners and edges, you can consider addingcoating protection angles to reduce the current density at the tips.

How the plastic molding process affects coating

(1) It's better to use a screw-type injection machine to make sure the B component in ABS plastic is evenly distributed. Besides that, you also need to check if the injection machine you use might cause internal stress in the part, which would affect the plating's adhesion.

(2) ABS plastic pellets easily absorb moisture. If you don't dry them, the part's surface will have bubbles, silver streaks, and look dull during molding. This messes up the plating's appearance and adhesion.

(3) The injection process parameters should be chosen to keep the part's internal stress as low as possible, and to avoid surface defects like gas marks or waves. For example, increasing the processing temperature and mold temperature a bit, lowering the injection pressure, shortening the holding time, or reducing the injection speed can all reduce internal stress in the part to some extent.

(4) You can't use oil-based release agents. Otherwise, the roughening process won't be even, and you can't guarantee the adhesion of the plated metal.

Post-treatment processes

Tests show that heat treatment and surface conditioning can reduce or eliminate internal stress, increasing the plating's adhesion by 20% to 60%. When ABS plastic parts are heat-treated, their internal molecules rearrange to become more evenly distributed—especially the butadiene particles, which form a spherical structure—greatly reducing internal stress. Extending the heat treatment time properly can minimize internal stress. Using a surface conditioner on plastic parts not only gets rid of internal stress but also removes oil, thus improving the bonding strength of the plating.

In high-low temperature impact tests, parts without any post-treatment bubble, while those that have been post-treated show no obvious changes. This proves that post-treatment can significantly reduce the internal stress of the parts.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk