The cavity balance generally refers to products with multiple cavity. In the injection process, the cavity of each product needs to be filled at the same time as possible to reach cavity balance.

1. Reasons for cavity Balance:

When the plastic enters the cavity through the flow channel, the melt has a certain temperature, pressure and speed. All three variables are time-dependent, which means that the value of each variable will change over a short period of time until the filling is complete.

For example, melt temperature decreases with time. If the melt temperature is injected at 280 ° C, after one second, the melt temperature is lower than 280 ° C. The final size and quality of each injection molded product depends on temperature, pressure and speed. If the two cavity are not filled with similar filling conditions, the two parts produced by each cavity will be different.

2. Unbalance of cavity distribution and its influence:

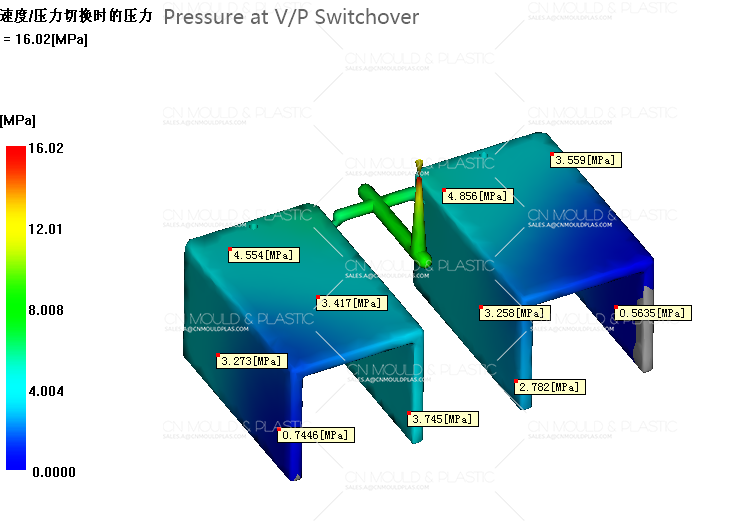

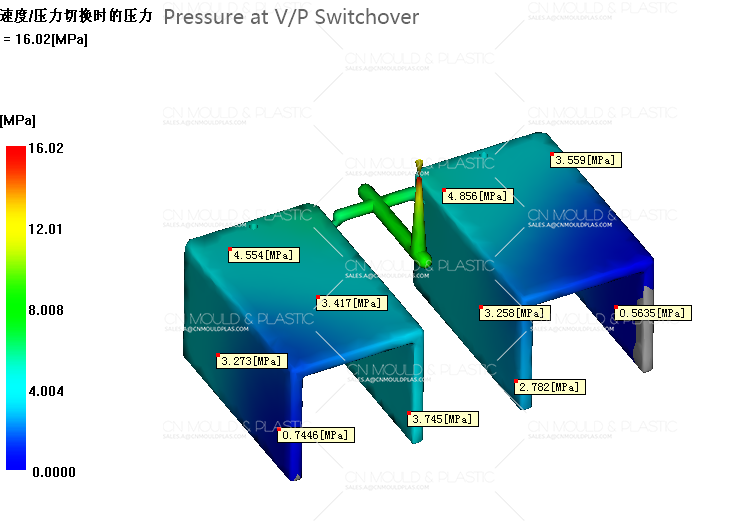

Unbalanced cavity distribution mean that in the injection mold, the layout of the space in the cavity is not uniform, resulting in inconsistent parameters such as pressure, temperature, speed, and flow during the injection process.

In this way, some areas of the plastic material may suffer from too much pressure or too high temperature, while others are too low, thus affecting the quality of the injection molding.

Specifically, the unbalanced distribution of cavity mainly has the following effects:

1) Uneven filling

Due to the unbalanced distribution of the cavity, the plastic material in some areas may reach the end point of filling early during injection molding, which leads to the problem of uneven filling.

If the filling is not uniform, the size, shape, surface quality of the molded product will have problems, such as warping, shrinkage and so on.

2) Venting is difficult

Unbalanced cavity distribution is not conducive to venting. Because the pressure in various areas is different, the gas is difficult to vent smoothly, which will lead to inadequate venting problems.

If there are bubbles in the formed product, it will not only affect the normal use, but also lead to material waste, low production efficiency and other problems.

3. How to solve the problem of unbalanced cavity distribution?

1) Consider the uniformity of cavity layout in mold design, and make cavity distribution more uniform as far as possible.

2) Reasonably adjust the injection position and flow rate of plastics, so that the injection parameters of different regions are more unified.

3) Use adjustable mold temperature control system to adjust the temperature of different areas, so as to achieve better filling effect.

4) Make reasonable use of the Venting System of the mold, improve the sealing and venting performance of the mold, and help the gas to be quickly discharged from the cavity.

In short, during the injection molding process, the unbalanced distribution of the cavity will affect the injection molding quality, resulting in various defects. Therefore, in the mold design and injection process, attention should be paid to optimizing the cavity distribution and selecting the appropriate process parameters in order to minimize the occurrence of injection defects.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk