At the heart of the injection unit lies a critical component: the barrel, also known as the plasticizing or injection cylinder. Working in close partnership with the screw, this cylindrical chamber houses both the plastic material and the rotating screw itself. Heater bands wrapped around its exterior supply the necessary heat to gradually melt the resin as it is conveyed forward. It is within this precisely controlled environment that the plastic is homogenized, melted, and ultimately injected into the mold.

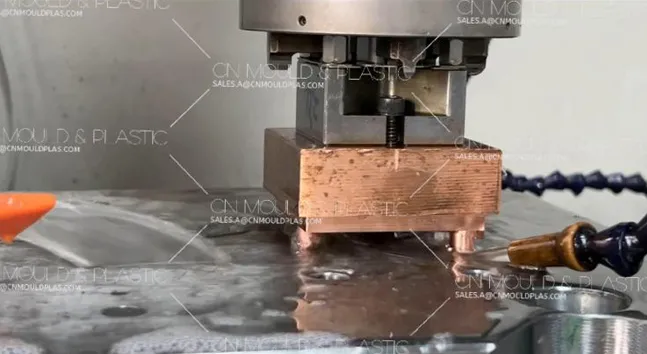

To endure continuous friction, high pressure, and repeated thermal cycles, the barrel is constructed from high-strength, wear-resistant materials. Its inner surface is often hardened or coated to extend service life and maintain processing consistency. Along with the screw, the barrel enables the essential functions of feeding, melting, and metering—making it indispensable to stable and efficient injection molding.

a. These things are usually made from special tough alloy steels, sometimes nitrided for a hard surface. To really fight off wear and corrosion from heat and pressure, sometimes they make the main body from carbon steel and then line the inside with a super-hard alloy sleeve, like Xaloy.

b. Everything about its design – the size, the feed throat shape, how thick the walls are, where the cooling channels go – all that has to be carefully figured out based on the pressure it handles and the temperatures needed.

c. The inside needs to be really smooth and extremely hard.

1. Taking the Barrel Apart

a. First, take out the bolts holding the hopper to the barrel flange.

b. Disconnect the water hoses from the cooling jacket.

c. Unplug the wires for the thermocouples and heater bands.

d. Loosen the bolt on the coupling and slide the coupler off. Remove the shaft sleeve too.

e. Use a wrench to loosen the screws on the barrel flange so you can separate the barrel from the injection unit mount.

f. Hoist the barrel up just enough, then carefully ease it off the drive shaft.

g. Lower the barrel onto a workbench. You wanna take the screw out while it's still warm.

h. Clean out any leftover plastic from the barrel immediately. Use a brass brush or emery cloth – don't use steel tools or anything hard that could scratch it!

2. Cleaning the Barrel

a. Take off the hopper. Cover the feed opening with a cap. Push a cleaning brush through the barrel from one end, going back and forth to scrub the inside walls and get all the gunk and dust out.

b. Once the big stuff is gone, wrap a clean cloth around your brush and run it through again to wipe up any leftover residue.

c. Blow compressed air in through the feed throat to clear out any last bits of debris. You can use the same method to clean the nozzle, check ring, and screw.

3. Putting the Barrel Back In

a. Basically, do the disassembly steps in reverse order.

b. Once the barrel and nozzle flange are in place, put the bolts in. You'll probably need a cheater bar (like a 400mm pipe) to tighten them properly. Be careful not to over-tighten and strip them! The torque needed is around 110 N·m.

c. When tightening the bolts on the barrel face, do it in stages: just snug them up on the first pass, then gradually increase the torque on the second and third passes, keeping it even on all bolts.

d. Slot the heater bands back onto the barrel in the right order. Once they're positioned, tighten them by turning clockwise.

e. Screw the thermocouples back into their holes. Make sure those holes are totally clean first.

f. To fix the nozzle: Open it up, screw it into the front of the barrel by hand. Then use a spanner wrench on the notches to give it a final tighten. Secure the spring, washer, and link. (Watch the orientation of the link!). Screw the needle valve into the body. Finally, hand-tighten the nozzle until it stops, then use an SVN wrench for the final tighten. The valve body needs to be tighter than the nozzle, or you might pull both out when you try to remove the nozzle later.

g. Putting the screw head back on: Clamp the screw in a vise, but use brass plates on the jaws to protect it. Once it's secure, you can work on it. Put the check ring on. Remember, the screw head has left-hand threads, so you turn it clockwise to tighten. Once it's hand-tight, put a special wrench on it and give the handle a few light taps with a mallet to really seat it.

h. Put the nozzle heater band on and connect its wires to the right terminals.

i. Put the protective covers (heater guards) back on.

4. Checking/Inspecting the Barrel

You usually inspect the barrel after taking the screw out, with the barrel on a bench. Use calipers to measure the inside diameter (ID) at the front and back. Compare those measurements to the original specs and the recommended clearance with the screw to see how worn it is. Also, just look inside for obvious scratches or scoring.

a. Measure the barrel's ID with calipers first.

b. Based on that, pick the right extension head for a dial bore gauge.

c. Put the bore gauge in the barrel, set it, and zero it.

d. Move the gauge in and out along the barrel's length a few times to check for wear (cylindricity error – if it's tapered or wavy).

e. Rotate the gauge at different spots to check for out-of-roundness (roundness error).

f. Use all these measurements, plus how the surface looks, to figure out how worn the barrel really is.

5. Fixing/Repairing the Barrel

a. If the inside just has minor scratches or wear, you can sometimes fix it by honing with an oil stone, emery cloth, or a honing tool on a lathe.

b. For honing on a lathe: clamp the barrel in the lathe chuck, mount the hone tool on the tool post, and then do the honing.

c. If the wear is bad, you might need to machine the inside to remove the damaged layer, then hone it back to the right smoothness (Ra ≤ 1.6 µm). It might need re-heat-treating or re-carburizing afterwards.

d. If the clearance between the barrel and screw is way too big, one option is to fit a hardened alloy sleeve inside the barrel. Sometimes they use centrifugal casting to put a new hard layer on the inside. Then you just machine and hone it back to the correct size.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk