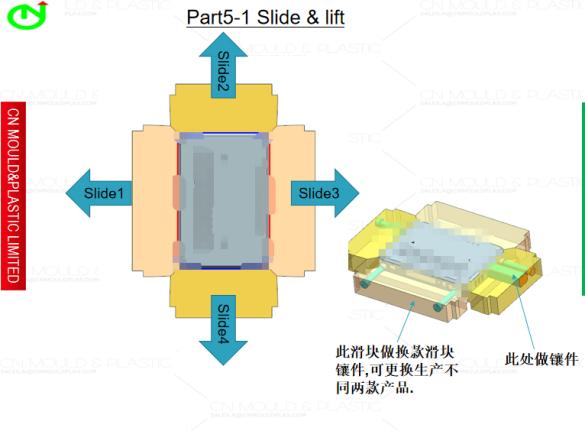

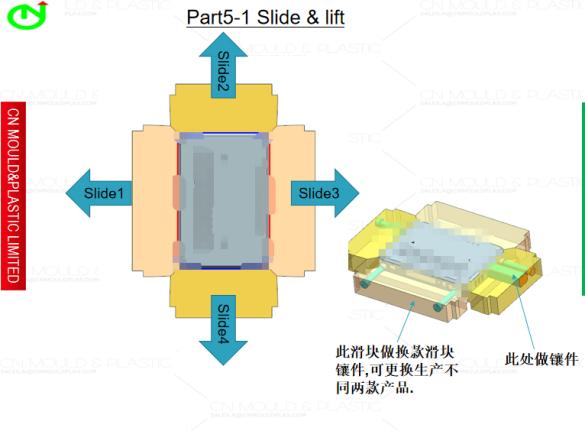

When a plastic part contains side holes, side undercuts, or protrusions that are not parallel to the mold opening direction, the corresponding mold components will obstruct part ejection after molding. Except in rare cases where forced ejection is feasible, it is generally necessary to design these components as laterally movable cores. These cores must be retracted before part ejection, then reset after mold closing. The mechanism responsible for this lateral movement is called the core-pulling mechanism. As a fundamental mechanism in injection molding, it essentially serves as a device for part release.

There are two operational sequences for such molds:

1. Lateral core-pulling completes before part ejection during mold opening.

2. Core-pulling occurs simultaneously with part ejection.

Classification and Characteristics of Common Core-Pulling Mechanisms

Based on structural requirements, mechanisms are categorized as internal or external core-pulling. According to power source, they are classified as:

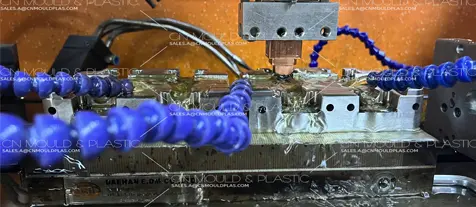

1. Mechanical Core-Pulling

Utilizes the mold opening force to actuate lateral movement through transmission components. Advantages include:

Operational convenience

High production efficiency

Compatibility with automation

Despite complex structures, these remain widely used. Main types include:

Angled leader pin systems

Dog-leg cam mechanisms

Angular slide systems

Rack and gear systems

Spring-assisted systems

2. Hydraulic/Pneumatic Core-Pulling

Employs pressurized oil/air as power source with dedicated cylinders. Key features:

Smooth transmission

Long retraction distances

High pulling force

Flexible operation timing

These systems operate independently of mold opening/closing cycles, making them ideal for large molds. Hydraulic systems are more common than pneumatic due to standard equipment on injection molding machines.

Design Essentials

1. Ensure sufficient guiding length for moving components. Large slides require anti-wear measures.

2. Focus on reliability and rigidity of transmission components in complex mechanisms.

3. Incorporate robust locking devices to secure cores during mold clamping.

4. Implement precise positioning systems to prevent accidents during mold closing.

5. Prioritize simplified solutions that meet product requirements while minimizing structural complexity.

6. Verify machine specifications for adequate opening stroke and force when necessary.

Prevent interference between side cores and ejector pins during mold closing. When unavoidable, incorporate early-return mechanisms to protect mold components.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk