In injection molding, there are several temperatures you need to keep an eye on: the barrel temperature, nozzle temperature, and mold temperature, to name a few. The first two mainly affect how the plastic melts and flows, while the mold temperature is all about how the plastic flows and cools. Before you start injecting, make sure the material, drying hopper, mold, and hydraulic oil are all at the right temperatures.

Barrel temperature

Every type of plastic has a different flow temperature. Even the same plastic, if it comes from different sources or has different grades, will have different flow and decomposition temperatures. That’s because their average molecular weight and molecular weight distribution are different. Plus, plastics melt differently in different types of injection machines, so the barrel temperature won’t be the same either.

The plastic’s temperature is controlled by the barrel, so the barrel temperature directly affects how well the plastic melts. When picking a barrel temperature, the main goal is to make sure the plastic melts properly, injects smoothly, and doesn’t start to break down in spots. First off, it depends on the plastic’s properties. Usually, you have to heat the plastic above its viscous flow temperature (Tf) or melting point (Tm) so it can flow and be injected. So the highest temperature at the end of the barrel should be above Tf or Tm, but definitely below the plastic’s decomposition temperature (Td).

For heat-sensitive plastics where the range between Tf and Td is narrow, or plastics with lower molecular weight or a wider molecular weight distribution, keep the barrel temperature on the lower side – just a bit above Tf is enough. For plastics with a wider range between Tf and Td or higher molecular weight, you can go a bit higher. That way, you take advantage of their lower viscosity.

You also need to think about how long the plastic sits in the heated barrel. This is super important for heat-sensitive plastics like polyoxymethylene—or engineering resins like PEEK that demand strict peek mold control. So in production, besides strictly controlling the maximum barrel temperature, you have to watch how long the plastic stays in the barrel (meaning how the production cycle affects the material temperature).

The design of the product and mold matters too. When making thin-walled products, the plastic has a hard time flowing and cools down quickly, losing its ability to flow. So you’ll need a higher barrel temperature. For thick-walled products, the flow resistance is lower, and since they take longer to cool, the injection cycle is longer – the plastic sits in the barrel longer, so you should use a lower temperature. If the product is complex or has inserts, the melt has to travel a long, twisty path, so again, go for a higher barrel temperature.

Different plastics need different temperature focuses. For example, ABS and PC: ABS’s viscosity barely changes with temperature. So once ABS reaches its flow temperature, cranking up the barrel temperature more won’t help lower the viscosity to fill the mold – it does nothing. Especially for colored ABS parts, it’s actually bad. Most color pigments are organic and break down at high temperatures, making the color fade or spotty.

PC is the opposite. A small temperature increase makes its viscosity drop a lot. From what I’ve read, in the processing temperature range, raising the barrel temperature by 10-20°C can cut the injection pressure in half. On the flip side, if the temperature is 10-20°C below the normal range, the pressure doubles. This effect is worse if the nozzle or mold is too cold, so with PC parts, you have to make sure the material and mold are hot enough.

To check if the material temperature is right, try injecting into the air at low pressure and speed. Good temperature means the plastic comes out strong, no bubbles, doesn’t curl, looks shiny, and flows steadily.

Nozzle temperature

When the melt goes through the nozzle, the high shear rate makes it heat up a bit. Also, to stop the melted plastic from dripping, the nozzle temperature is usually set a bit lower than the highest barrel temperature. If you’re using an extended nozzle, use a heating coil that matches its length or turn up the temperature a bit – otherwise, cold plastic might clog the nozzle.

But don’t set the nozzle temperature too low – usually 5-10°C below the maximum barrel temperature is enough. If it’s too cold, the injection pressure will go up, or the material might solidify early, ruining the part.

Melt temperature

This is the temperature of the melted plastic right when it’s time to inject, after it’s fully melted, depending on the production cycle. It’s the actual temperature the plastic reaches when melted. The barrel temperature setting depends on this melt temperature, the screw speed, back pressure, shot size, and injection cycle. You can measure it at the nozzle or by injecting into the air. The barrel temperature is just a guide – if you’ve never processed that specific grade of plastic before, start with the lowest setting.

Mold temperature

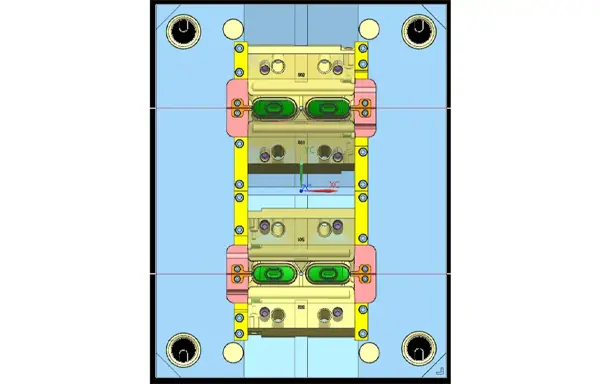

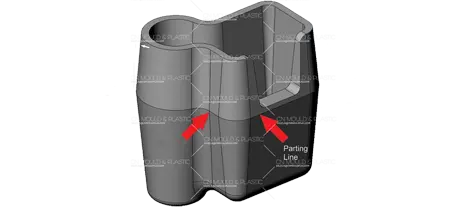

Mold temperature directly affects how the melt fills the mold and how the product cools. It’s one of the main things that determines the cycle time and product quality. Choosing the right mold temperature depends on the material, the product’s size and shape, and the mold design.

For amorphous plastics, mold temperature mainly affects the melt’s viscosity (how easily it flows). If the material has low viscosity (like PS), you can use a lower mold temperature to speed up production. If it has high viscosity (like PC), you need a higher mold temperature to help it fill the mold.

For crystalline plastics, a higher mold temperature means the material takes longer to cool, leading to higher crystallinity – the product will be harder and stronger but have more shrinkage. A lower mold temperature means faster cooling, lower crystallinity – the product will be softer and more flexible.

For parts that need tight dimensional accuracy, use a lower mold temperature to control shrinkage.

For parts that need a glossy surface or are thin and complex, use a higher mold temperature to help filling. For thick-walled parts, also use a higher mold temperature. If the mold is too cold, the temperature difference between the inside and outside of the part can cause sinks, voids, or high internal stress.

Oil temperature

This is the temperature of the hydraulic oil in the injection machine’s hydraulic system. It’s technically a hydraulic system issue, but if the oil gets too hot, it affects the oil’s thickness, causes bubbles in the system, and increases oil leakage. This leads to fluctuations in system pressure and flow, which make the injection pressure and speed pulse. That messes up the injection process and, in the end, the quality of the part.

So when adjusting the injection process, keep an eye on the oil temperature. You can control it by adjusting the cooling water flow through the hydraulic oil cooler. For positive displacement hydraulic injection machines, keep the oil temperature between 5-55°C.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk