The low pressure molding process encapsulates parts safely in seconds with an environmentally friendly hot melt adhesive, providing superior waterproofing and protection against temperature extremes, harsh chemicals, shock, and vibration. This makes it an excellent technique for waterproofing electronics. Low-pressure molding occupies a unique position between potting and high-pressure injection molding. Unlike potting, which can require up to seven steps, the low pressure molding process can be completed in three simple steps, effectively improving the waterproofing of electronic components. The cost of an overmolded part can be half that of a potted part due to process step reduction, faster processing speed, significantly increased throughput, and lower material, shipping, and labour costs.

Because of the tight overmolding tolerances, design engineers have more room and flexibility in the final assembled products. For example, by potting method, the filling space above the electronic components must be more than 5mm. Otherwise it's too difficult for the potting melt to flow through. By low pressure molding, the filling gap can be less than 5mm as the injection pressure can be up to 1000 MPa and it helps the hot melt going through narrow area.

Low Pressure Molding provides design capabilities that go far beyond the form-fit-function of conventional circuit board protection materials. By manipulating the runner distance and depth, thinner gaps can be filled first to avoid "welding lines" between faster flowing and slower flowing area.

Low pressure molding materials can be skylined around components and electronics to save material, reduce end product weight, and provide more precise encapsulation.

Low pressure molding improves the aesthetics of finished products. The material serves as the housing, eliminating the need for additional parts.

Low injection pressure allows for easy molding around fragile components, and the material's rapid cooling times during overmolding reduce heat exposure to sensitive electronics.

One of the primary advantages of low pressure molding over traditional potting is the simplified manufacturing process. Instead of potting, which takes eight steps to encapsulate a part, low pressure molding requires only three.

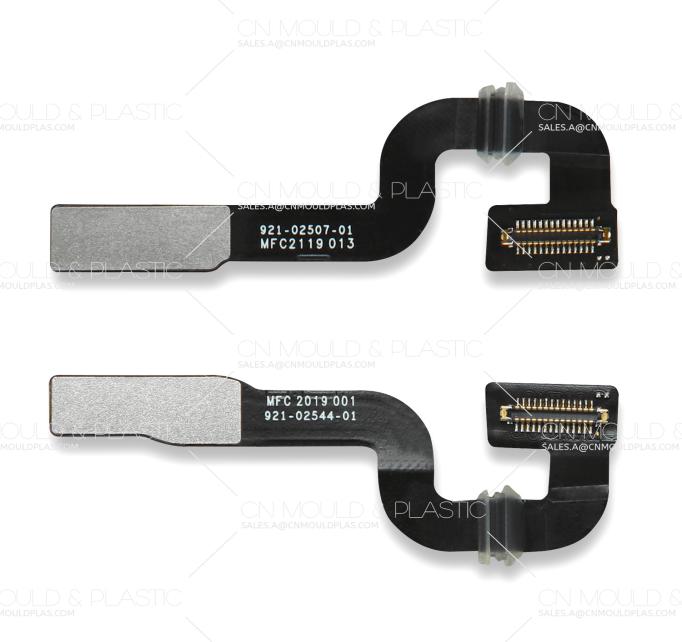

The main advantage of low pressure molding is reflected in its name. When applied to a circuit board, high pressure injection molding's highly viscous material will sheer off the components in seconds. Low pressure molding is ideal for overmolding sensitive electronics like sensors, switches, and batteries.

Low pressure molding is a safe and delicate process that falls between high pressure injection molding and potting. With its short cycle times and low pressures, it is the ideal circuit board protection solution.

From material and design flexibility to IP 65-68 submersion protection, low pressure molding offers superior protection for your parts or devices.

-0.webp)