When a product completes production and readies for delivery, it stands at the final gateway before reaching the customer—this is where Outgoing Quality Control (OQC) takes center stage. As the last line of defense in quality assurance, OQC is far more than a routine check: it directly safeguards customer satisfaction, upholds a company’s brand reputation, and prevents costly returns or disputes caused by substandard goods.

OQC Inspection Standards & Procedures

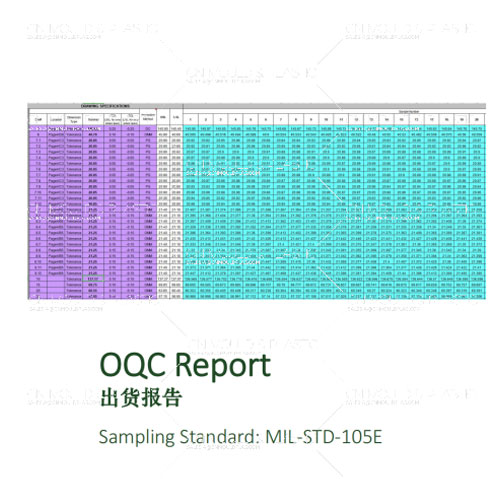

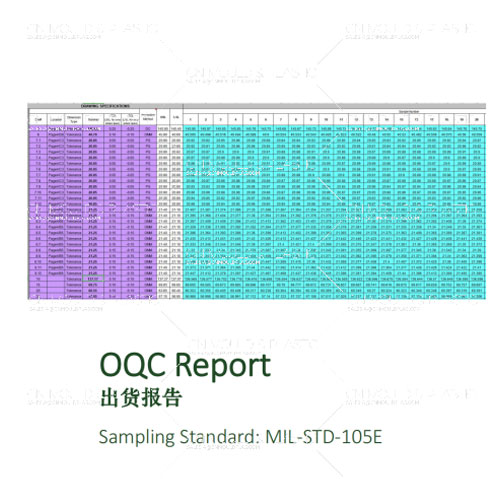

Inspectors conduct sampling inspections in accordance with MIL-STD-105EII, with specific criteria categorized by product type:

• For Category A and B products: Sampling inspection is mandatory.

• For Category C products: Inspection Level (IL) = D, Acceptable Quality Level (AQL) = MA (Major Defects) = 1.5, MI (Minor Defects) = 2.5.

Key Inspection Items

Routine checks cover critical product attributes, including but not limited to:

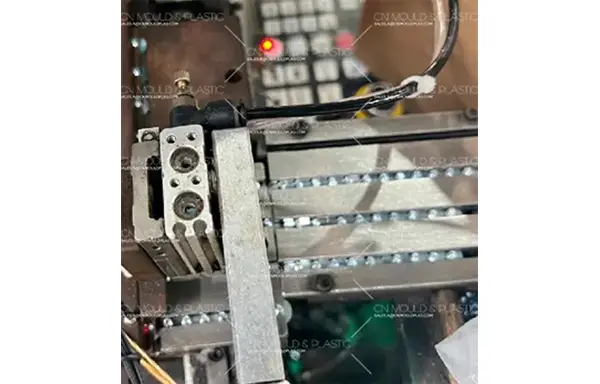

• Dimensional accuracy

• Weight consistency

• Functional performance (e.g., operational tests for mechanical or electronic products)

Inspection Result Handling

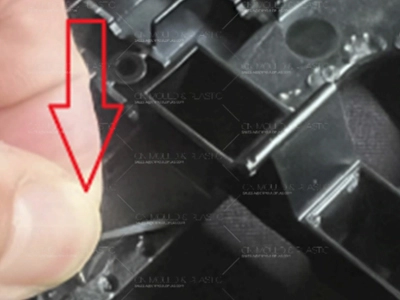

• If non-conformities are found during inspection: Inspectors must expand the scope to test all sampled products (instead of continuing with random sampling) to fully assess the defect rate.

• If products are deemed unqualified:

a. OQC inspectors document the non-conformities in a Non-Conforming Report (NCR).

b. After verification by the Inspection Supervisor, OQC staff stamp a red "Unqualified" seal on the outer carton labels of the non-conforming products.

c. The inspection results (including defect details) are recorded in the OQC Inspection Report.

d. Non-conforming products undergo a review based on authority levels:

▪ If the issue falls within the Inspection Supervisor’s jurisdiction, the supervisor chairs a Material Review Board (MRB) meeting to decide on disposal.

▪ If the non-conforming batch exceeds the supervisor’s authority, the next-level quality management personnel organizes the MRB meeting, involving representatives from the production workshop, engineering, and quality departments. The responsible department must propose corrective actions.

• If products are deemed qualified:

a. A blue "OQC Pass" seal is affixed to the products. This seal must include three key pieces of information: inspection date, inspection location, and OQC inspector code.

b. The shipping process is authorized to proceed.

Rework & Re-inspection Rules for Non-Conforming Products

When a decision is made to rework non-conforming products, the following steps must be followed:

1. The production workshop, engineering, and quality departments collaborate to define a clear rework process tailored to the specific defects (e.g., adjusting assembly steps for functional issues or reworking packaging for labeling errors).

2. OQC inspectors supervise and verify the implementation of the rework process to ensure compliance with standards.

3. Temporary hold for unconfirmed solutions: If no rework plan is available immediately (e.g., defects require further technical verification), the products must be detained and stored separately to prevent mixing with qualified goods.

Critical Rework Location Rules

• Rework operations are not allowed in the warehouse to avoid cross-contamination or confusion with inventory.

• All products requiring rework must be retrieved from the warehouse by rework personnel and processed in a designated rework area.

• Exception approval: Under special circumstances (e.g., urgent delivery deadlines), a formal application must be submitted to the warehouse management and quality department supervisors. Rework in a designated warehouse area is only permitted after approval is granted.

Post-Rework Re-inspection

After rework is completed, OQC inspectors must perform a full re-inspection of the products to confirm they meet quality standards before releasing them for shipping.

Pre-Shipping Verification & Inventory Re-Inspection

Pre-Shipping Checks

Before products are loaded for delivery:

1. OQC inspectors cross-verify the following documents and details:

◦ Shipping Order (to confirm customer and order information)

◦ Standard Inspection Procedure (SIP, to ensure compliance with inspection requirements)

◦ Booking Note, container number, and truck license plate (to ensure goods are loaded into the correct container/truck)

2. Inspectors confirm that goods are assigned to the designated customer and record the inspection time and results in the OQC Inspection Report.

Inventory Re-Inspection (3-Month Rule)

For products stored in the warehouse for 3 months or longer:

1. The warehouse keeper must notify OQC to conduct a re-inspection.

2. OQC follows MIL-STD-105EII for sampling:

◦ Category A/B products: Standard sampling as per initial inspection.

◦ Category C products: IL = I, AQL = MA=1.5/MI=2.5.

3. Results are documented in the inspection report. If non-conformities are found:

◦ OQC issues an NCR, which is verified by the Inspection Supervisor.

◦ The supervisor convenes engineering, production, and quality personnel to confirm the defects and document the disposal plan in the NCR. Rework personnel then execute the plan.

"Special Acceptance" (Deviation Approval) Process

In rare cases where non-conforming products are approved for shipment (e.g., urgent customer needs with minor defects), the "Special Acceptance" process applies:

1. Sign-off is required from the authorized supervisors of the engineering, production, and sales departments.

2. Customer consent is mandatory if necessary (e.g., defects that may affect product use but are acceptable to the customer).

If "Rework" is chosen instead:

• Engineering and quality personnel provide on-site guidance for the rework.

• OQC performs a re-inspection after rework to confirm compliance.

Record Retention Requirement

All OQC-related records (including inspection reports, NCRs, MRB meeting minutes, and rework records) must be retained for at least 2 years to support quality traceability, audits, and continuous improvement.

Core OQC Responsibilities & Key Notes

To ensure consistent OQC performance, inspectors must adhere to the following guidelines:

1. Complete daily inspection tasks on time in accordance with the OQC inspection schedule.

2. Conduct inspections strictly in line with requirements outlined in the SIP, sample products, design drawings, and technical documents. No deviations from standards are allowed.

3. Issue an NCR promptly when non-conformities are found, distribute it to relevant departments for review, and mark non-conforming products with a red "Non-Conforming" seal to isolate them from qualified goods (preventing accidental shipment).

4. Ensure 100% re-inspection for all reworked products. Only products that pass the re-inspection can be approved for shipping.

By standardizing OQC processes and enforcing these guidelines, businesses can minimize the risk of defective products reaching customers, protect brand reputation, and build long-term customer trust.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk