(1) Barrel Temperature

Feed Zone: 60-90°C (80°C)

Zone 1: 260-290°C (280°C)

Zone 2: 260-290°C (280°C)

Zone 3: 280-290°C (290°C)

Zone 4: 280-290°C (290°C)

Zone 5: 280-290°C (290°C)

Nozzle: 280-290°C (290°C)

Temperatures in parentheses are recommended starting points at 35% and 65% stroke utilization and flow length to wall thickness ratio of 50:1 to 100:1. Temperatures in the Feed Zone and Zone 1 directly affect feeding efficiency; increasing them can promote more consistent feeding.

(2) Melt Temperature 270-290°C

(3) Barrel Residence Temperature 240°C

(4) Mold Temperature 60-100°C

(5) Injection Pressure 100-160 MPa (1000-1600 bar). Up to 180 MPa (1800 bar) may be required for thin-wall sections with long flow paths (e.g., cable ties).

(6) Holding Pressure Approximately 50% of injection pressure. Short holding time is sufficient due to relatively rapid material solidification. Reducing holding pressure minimizes internal stresses.

(7) Back Pressure 2-8 MPa (20-80 bar). Requires precise adjustment, as excessively high back pressure can cause uneven plastification.

(8) Injection Speed Relatively fast speeds are recommended. The mold must be well-vented to avoid burn marks.

(9) Screw Speed Generally high, with a peripheral speed of 1 m/s. However, it is preferable to set the screw speed lower, provided plastification completes before the end of the cooling time. Requires low screw torque.

(10) Metering Stroke (0.5-3.5)D

(11) Cushion 2-6 mm, depending on metering stroke and screw diameter.

(12) Pre-Drying 4 hours at 80°C (unless feeding directly from a sealed container). Nylon is hygroscopic and must be stored in moisture-proof containers and closed hoppers. A water content >0.25% by weight adversely affects processing.

(13) Regrind Up to 10% regrind can be used.

(14) Shrinkage 0.7-2.0%. For 30% glass-filled grades: 0.4-0.7%. If mold temperature exceeds 60°C, parts should be cooled gradually to reduce post-molding shrinkage, resulting in better dimensional stability and lower internal stress. Steam tempering is recommended. Stress can be checked using a solvent test.

(15) Gating System Pin-point, submarine, edge, and direct sprue gates are suitable; use blind holes and cold slug wells to trap cold material; hot runner systems can be used. Due to the narrow processing window, hot runners must provide closed-loop temperature control.

(16) Machine Shutdown No purging with other material required. Melt can remain in the barrel for up to 20 minutes; beyond this, thermal degradation is likely.

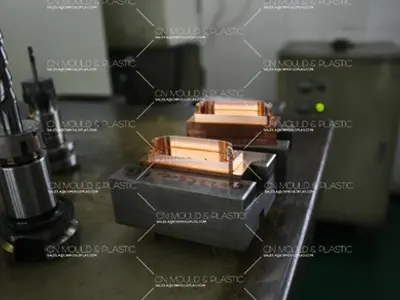

(17) Barrel Equipment Standard screw (special geometry available for higher plastification capacity), non-return valve, open nozzle. For glass-filled grades, a bimetallic barrel with high wear resistance is required.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk