Implementation Procedures for Attribute Sampling Inspection

1. Inspection Procedures

2. Specification of Quality Characteristics of Unit Products

In product counting standards or purchase contracts, technical performance, technical indicators, appearance, and other quality characteristics of unit products must be clearly defined.

3. Classification of Nonconformities

Divide nonconformities into CR, MJ, and MN according to actual needs (that is, the so - called Class A, Class B, and Class C nonconformities. It is also possible to use CR for Class A, MJ for Class B, and MN for Class C). If the product is relatively simple, it can also be divided into two categories of nonconformities or not distinguished at all.

4. Specification of Acceptable Quality Level (AQL)

In product technical standards or purchase contracts, the acceptable quality level should be determined through negotiation between the ordering party and the supplying party. Different acceptable quality levels should be specified for different nonconformity categories. The AQL value for Class A nonconformities must be smaller than that for Class B nonconformities; similarly, the AQL value for Class C nonconformities should be larger than that for Class B nonconformities. In the sampling table, for parts where AQL is less than 10, the AQL value can be either the number of nonconformities per 100 unit products or the number of nonconforming products per 100 unit products. For those nonconforming quality levels with AQL greater than 10, it is only the number of nonconformities per 100 unit products.

5. Specification of Inspection Level (IL)

There are 3 general inspection levels: I, Ⅱ, and Ⅲ.

There are 4 special inspection levels: S - 1, S - 2, S - 3, and S - 4.

In general cases, the general inspection level Ⅱ is usually adopted; when a lower discrimination ability is required, the general inspection level I can be adopted; when a higher discrimination ability is required, the general inspection level Ⅲ can be adopted; special inspection levels are only applicable when a smaller sample size must be used, and a larger risk of misjudgment can or must be allowed.

6. Formation and Submission of Inspection Batches

Unit products are simply aggregated to form inspection batches, or inspection batches can be formed in other ways. Inspection batches can be the same as or different from submission batches, sales batches, and transportation batches. Usually, each inspection batch should consist of unit products of the same type, grade, and production conditions, that is, with basically the same production time.

7. Selection of Sampling Plan Types

As long as the specified acceptable quality level and inspection level are the same, regardless of the type of sampling plan used for inspection, their discrimination ability for batch quality is basically the same.

8. Retrieval of Sampling Plans

Retrieve sampling plans from the sampling table according to the sample size and acceptable quality level. For example: A factory has a total of 800 X88 frames to be shipped to Ningbo. OQC inspector Li Mou conducts pre - shipment inspection on them. Find the normal single sampling plan for OQC inspector Li Mou.

(1) It is found in the inspection documents that the X88 frame belongs to Class A goods. According to the GB2828 - 87 standard, the normal inspection with the general inspection level Ⅱ (IL = Ⅱ) is adopted. The AQL for major defects (MJ) is 1.5%, and the AQL for minor defects (MN) is 2.5%. See Table 1 - 1.

Table 1-1 GB 2828—87 Sample Size Code Table and Sampling Plan

| Lot Size Range | General Inspection Level | Sample Code | Sample Size | AQL |

| I | II | III | 1 | 1.5 | 2.5 | 4 |

| AC | RE | AC | RE | AC | RE | AC | RE |

| 1月8日 | A | A | B | A | 2 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| 9月15日 | A | B | C | B | 3 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| 16 - 25 | B | C | D | C | 5 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 2 |

| 26 - 50 | C | D | E | D | 8 | 0 | 1 | 0 | 1 | 1 | 2 | 1 | 2 |

| 51 - 90 | C | E | F | E | 13 | 0 | 1 | 1 | 2 | 2 | 3 | 2 | 3 |

| 91 - 150 | D | F | G | F | 20 | 0 | 1 | 1 | 2 | 3 | 4 | 3 | 4 |

| 151 - 280 | E | G | H | G | 32 | 1 | 2 | 2 | 3 | 4 | 5 | 5 | 6 |

| 281 - 500 | F | H | J | H | 50 | 1 | 2 | 2 | 3 | 5 | 6 | 7 | 8 |

| 501 - 1200 | G | J | K | J | 80 | 2 | 3 | 3 | 4 | 6 | 7 | 8 | 10 |

| 1201 - 3200 | H | K | L | K | 125 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 11 |

(2) In the sample size code table, at the intersection of the row containing N = 800 (501 - 1200) and the column where IL = Ⅱ, the sample size code is read as J.

(3) In the normal inspection single sampling table, read the sample size as 80 from the column corresponding to the sample size of J.

(4) Move right from 80, and at the intersections with AQL = 1.5 and AQL = 2.5, read the judgment groups [3, 4] and [5, 6].

Therefore, the obtained normal inspection single sampling plan is as follows:

n = 80, Ac = 3, Re = 4; (MJ defects, i.e., major defects)

n = 80, Ac = 5, Re = 6. (MN defects, i.e., minor defects)

9. Sampling

The samples should be drawn in a way that can represent the batch quality. Generally, the current general principles adopted by injection molding factories are as follows:

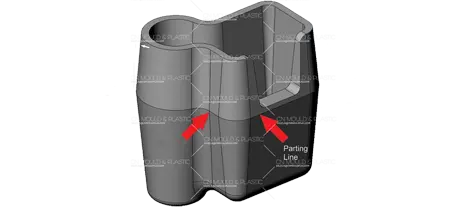

(1) When sampling during the production process, try to randomly (RANDOM) select samples from different time periods and different packaging boxes. For molds with multiple cavities, it is necessary to ensure that products from each cavity can be randomly selected.

(2) When sampling in the warehouse, samples must be randomly selected from products produced by different teams, on different production dates, by different machines, by different production workers, and from different packaging boxes. Different inspections and their results should be treated differently.

10. Inspection of Samples

Inspect each sample one by one according to the inspection items specified for unit products in the product technical standards and inspection instruction documents, and accumulate the total number of major or minor nonconforming products or the total number of nonconformities. The handling after inspection shall be carried out in accordance with the regulations of each factory's inspection management procedures.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk