Products made by injection molding of TPR/TPE are prone to flash.

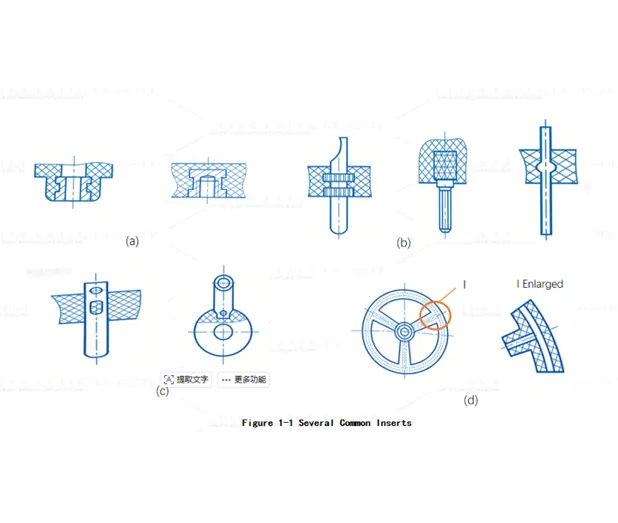

Flash on injection-molded parts, also known as overflow or burrs, mostly occurs at the joints of the upper modules of the mold, such as the parting surface, the gaps of ejector pins, the mating parts of sliders, the gaps of inserts, and the holes of ejector pins. If the flash is not corrected in time, it may affect the appearance of the product or the air exhaust during the mold-filling process. If the flash is too large, the debris generated during the demolding process may remain inside the mold, resulting in cold material in the product. In severe cases, it may cause permanent indentations on the mold. If the debris remains in moving parts, such as sliders and ejector pins, it may also lead to poor movement of the mold.

First, regarding the equipment:

(1) Insufficient clamping force of the molding machine. If the rated clamping force of the molding machine is less than the tension on the projected area of the product during the molding process, it will lead to gaps at the parting surface and cause flash.

Solutions to TPR/TPE injection molding defect problems: Pay attention to improving the mold accuracy, reducing the mold gap, increasing the clamping force, and enhancing the locking force.

(2) Insufficient clamping stroke of the molding machine. If the minimum clamping gap of the molding machine is larger than the thickness of the mold, the projected area of the product exceeds the maximum injection area of the injection press, the installation and adjustment of the injection press template are incorrect, the mold is installed incorrectly, the locking force cannot be maintained constant, the injection press template is not parallel, or the tie rods are unevenly deformed, it will lead to incomplete mold clamping and cause flash.

Solutions to TPR/TPE injection molding defect problems: Improve the defects of the injection molding machine.

Second, regarding the mold:

(1) The mold itself has poor accuracy, such as an improper fit of the parting surface, indentations or fatigue collapses on the parting surface, or an excessive gap between the parting surfaces.

Solutions to TPR/TPE injection molding defect problems: Improve the mold design.

(2) Unreasonable design, such as asymmetrical cavity distribution, which causes uneven tension during molding and is likely to generate flash at the parting surface; asymmetrical ejection mechanism, which causes torsion on the ejector pins during ejection and also generates flash; excessive exhaust gaps; too many inter - insertion structures of cavities and cores; offset of cavities and cores; non - parallel templates; template deformation; foreign objects falling on the mold plane; insufficient exhaust; and too large exhaust holes.

Solutions to TPR/TPE injection molding defect problems:

Third, regarding the process:

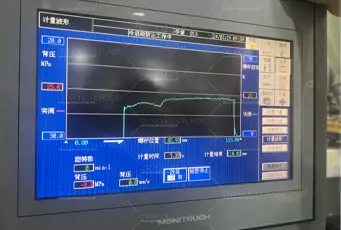

(1) Excessively high injection pressure or speed generates high - speed and high - pressure melt, causing elastic deformation at the joint of the mold and thus generating flash.

Solutions to TPR/TPE injection molding defect problems: Reduce the injection speed.

(2) Excessively high temperature. Whether it is the barrel temperature, nozzle temperature, or mold temperature, an excessively high temperature will reduce the viscosity of the plastic melt and enhance its fluidity, resulting in flash at the joint of the modules.

Solutions to TPR/TPE injection molding defect problems: Reduce the temperature.

(3) Excessive metering will create local high pressure inside the mold. If it occurs at the joint of the modules, it will produce flash.

Solutions to TPR/TPE injection molding defect problems: Reduce the metering amount.

Fourth, regarding the raw materials:

(1) Both too high and too low viscosity may cause product flash. Resins with too low viscosity, such as polyoxymethylene.

Solutions to TPR/TPE injection molding defect problems: Pay attention to improving the mold accuracy, reducing the mold gap, and increasing the clamping force.

(2) Resins with high viscosity will cause excessive flow resistance, increase the cavity back pressure during the mold - filling process, resulting in gaps at the mold parting surface and ultimately forming flash.

Solutions to TPR/TPE injection molding defect problems: Reduce the viscosity.

Fifth, regarding the cooling conditions: The part is cooled in the mold for too long.

Solutions to TPR/TPE injection molding defect problems: Avoid shrinkage from the outside to the inside, shorten the mold cooling time, and cool the product in hot water.

Products made by injection molding of TPR/TPE are prone to short shots.

Short shots refer to the incomplete phenomenon at the end of the material flow or the situation where some cavities in a multi - cavity mold are not fully filled.

(1) Poor material fluidity, so that the material flow cannot fill the entire cavity.

Solutions to TPR/TPE injection molding defect problems: Plastics with better fluidity should be selected.

(2) Poor exhaust of the mold prevents the air or the gas generated during plastic degradation from being discharged, resulting in too high pressure at the end of the cavity, and the material flow cannot fill the cavity.

Solutions to TPR/TPE injection molding defect problems: The countermeasure is to open exhaust grooves at the last filling position of the melt.

(3) Unreasonable design of the mold gating system. For example, improper gate position, too small gate size and runner size, which make the melt flow poorly, will all cause the material flow to fail to fill the cavity.

Solutions to TPR/TPE injection molding defect problems: The countermeasure is to improve the mold runner and gate design and expand the size of the gate and runner.

(4) The cooled material at the front of the material flow blocks the gate, runner, and injection port, resulting in insufficient filling of the product.

Solutions to TPR/TPE injection molding defect problems: At this time, the size of the cold slug well should be expanded.

(5) The inconsistent R values of the nozzle and the mold inlet reduce the effective amount and effective pressure of the melt, resulting in insufficient filling.

Solutions to TPR/TPE injection molding defect problems: The R values of the nozzle and the mold inlet should be ensured to be consistent.

(6) Excessive feeding amount reduces the effective pressure of the melt, and the material flow cannot fill the cavity.

Solutions to TPR/TPE injection molding defect problems: Reduce the feeding amount. The feeding throttle plug method can be used to control the excessive feeding of lubricated granular materials.

(7) In terms of the molding process, too low values of process parameters such as melt temperature, mold temperature, injection holding pressure, and injection speed will all shorten the mold - filling length and cause insufficient cavity filling.

Solutions to TPR/TPE injection molding defect problems: Appropriately increase the values of these parameters.

(8) Too low nozzle temperature reduces the temperature of the melt when it is injected into the mold cavity, thus shortening the mold - filling length.

Solutions to TPR/TPE injection molding defect problems: When opening the mold, the nozzle should be separated from the mold to reduce the influence of the mold temperature on the nozzle and keep the nozzle temperature within the specified process range.

(9) Too short injection stroke cannot meet the injection amount requirements of the product, resulting in insufficient feeding.

Solutions to TPR/TPE injection molding defect problems: At this time, the injection stroke should be adjusted, and the feeding port with granular bridging should be checked or the nozzle backflow valve should be adjusted.

(10) In a multi - cavity mold, the unbalanced layout of the gating system makes it impossible to fill the cavities far from the main runner.

Solutions to TPR/TPE injection molding defect problems: The cavity can be filled simultaneously by adjusting the width of the gate or making the lengths of each part of the runner consistent to balance the gating system.

(11) In a multi - cavity mold, improper setting of the injection speed at each stage causes insufficient filling of the product.

Solutions to TPR/TPE injection molding defect problems: The first - stage injection speed should be increased, that is, set for high - speed injection. When the material passes through the gate, the injection speed should be reduced and the time should be extended.

(12) Unreasonable product design. When the length and wall thickness of the product are not in proportion, the melt is likely to be blocked at the inlet of the thin - walled part of the plastic part, resulting in insufficient filling of the product.

Solutions to TPR/TPE injection molding defect problems: The ratio should be adjusted to an appropriate value. Usually, a wall thickness of more than 8mm or less than 0.5mm of the plastic part is not conducive to molding, and such wall thicknesses should be avoided.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk