By leveraging the excellent elasticity, pliability, and outstanding bending fatigue properties of plastics, lightweight and practical plastic connection components can be designed, which are widely applied in products such as electronics, instruments, daily necessities, and toys. Among them, plastic chains and fasteners are the two most common connection methods.

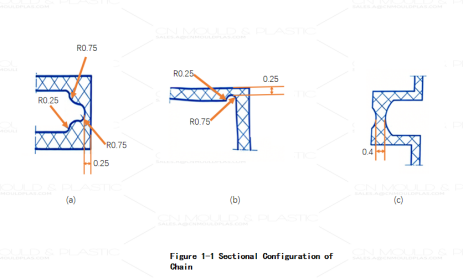

Common cross-sectional forms of chains are shown in Figure 1-1. The chain area should be relatively thin, typically ranging from 0.25 to 0.4 mm, and the melt flow direction must be perpendicular to the chain part. This orientation allows linear molecular chains to bend along their primary axis, enabling the chain to achieve a bending life of hundreds of thousands of cycles. If the flow direction is incorrect, the chain area is prone to breakage.

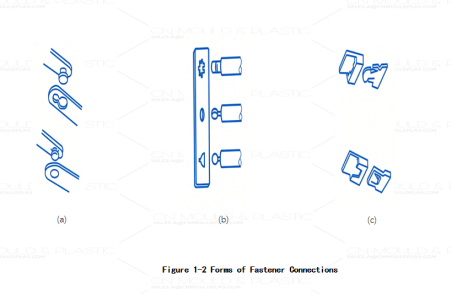

Fasteners made from soft or rigid plastics are widely used for connecting plastic sheets or films, as illustrated in Figure 1-2. Figure 1-2(b) shows a plug-type fastener connection, while Figure 1-2(c) depicts a strap-type fastener connection. The strength of the fastener depends on the connection method and the frictional properties of the materials. Fastener connections generally require materials with a certain degree of rigidity and toughness. Materials such as ABS, nylon, and polycarbonate are often chosen for fastener applications.