Polyethylene (PE) is a polymer prepared by the polymerization of ethylene monomers. In the industry, both ethylene homopolymers and copolymers of ethylene and α-olefins (<8%) are classified as polyethylene. Polyethylene plastics are plastics with polyethylene as the base material.

There are many varieties of polyethylene, and there are various classification methods. For the convenience of description, this book classifies it only according to its density. According to different densities, polyethylene can be divided into: high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), ultra-high molecular weight polyethylene (UHMWPE), and modified polyethylene. These types of polyethylene have large production volumes and wide applications, and they are the key points introduced in this book. Other varieties are not introduced here.

Main Properties

1.Structural Characteristics of Polyethylene

The molecules of polyethylene have a long-chain linear structure or a branched structure, and it is a typical crystalline polymer. In the solid state, the crystalline part and the amorphous part coexist. The degree of crystallinity varies depending on the processing conditions and the original treatment conditions. Generally, the higher the density, the greater the degree of crystallinity. The crystallinity of LDPE is usually 55% - 65%, and that of HDPE is 80% - 90%.

2.Basic Properties

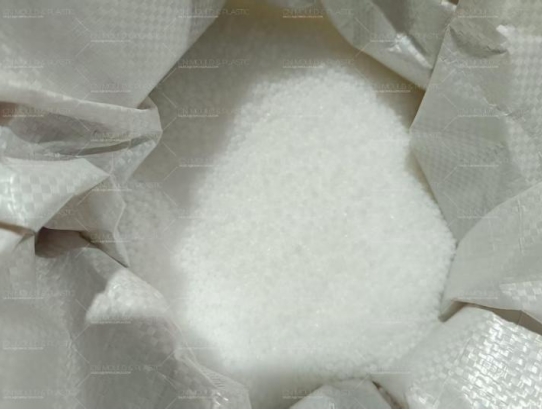

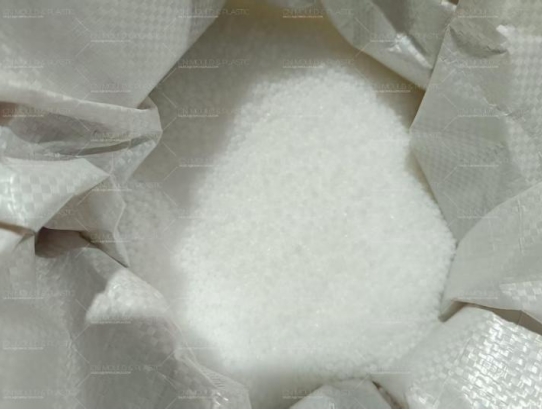

Polyethylene is a typical thermoplastic. It is an odorless, tasteless, and non-toxic flammable white waxy substance. It is lighter than water. When burning, it has the smell of paraffin. After softening, it takes on a spherical shape. The upper part of the flame is yellow, and the middle part is blue. It cannot self-extinguish. The PE resins used for molding processing are all waxy granular materials obtained by extrusion and granulation, and they appear milky white in appearance. Its relative molecular mass is in the range of 10,000 to 1,000,000. When the relative molecular mass exceeds 1,000,000, it is ultra-high molecular weight polyethylene (UHMWPE). The higher the relative molecular mass, the better its physical and mechanical properties, and it is closer to the requirements of engineering materials. However, the higher the relative molecular mass, the greater the difficulty of its processing. The melting point of polyethylene is 105-135°C. Polyethylene has excellent low-temperature resistance and can still maintain good mechanical properties at -60°C, but the service temperature is 80-110°C.

Polyethylene has good chemical stability. At room temperature, it can resist dilute nitric acid, dilute sulfuric acid, and solutions of hydrochloric acid, hydrofluoric acid, phosphoric acid, formic acid, acetic acid, ammonia water, amines, hydrogen peroxide, sodium hydroxide, potassium hydroxide, etc. at any concentration. However, it is not resistant to the corrosion of strong oxidants, such as fuming sulfuric acid, concentrated nitric acid, and the mixed solution of chromic acid and sulfuric acid. At room temperature, the above solvents will slowly erode polyethylene, while at 90-100°C, concentrated sulfuric acid and concentrated nitric acid will quickly erode polyethylene, causing it to be damaged or decomposed.

Under the action of the atmosphere, sunlight, and oxygen, polyethylene will age, change color, crack, become brittle, or powder, and lose its mechanical properties. At the molding processing temperature, due to the oxidation effect, its melt viscosity will decrease, and it will change color and show stripes. Therefore, attention should be paid during the molding processing, use process, or material selection. The modification method of PE is to add antioxidants, ultraviolet absorbers, or carbon black, etc., which can significantly improve its aging resistance.

Since polyethylene is a non-polar material, it has excellent electrical insulation properties. Its dielectric constant and dielectric loss are basically independent of temperature and frequency, and it has good high-frequency performance. It is an excellent raw material for manufacturing wire and cable insulation materials.

When polyethylene and its products are under stress or the action of residual stress inside the products, and they come into contact with polar solvents or vapors such as alcohols, aldehydes, ketones, esters, and surfactants, cracks will occur. This phenomenon is called stress cracking. Usually, the lower the relative molecular mass, the more serious the cracking. When selecting materials for processing, blending polymers such as polyisobutylene can reduce or eliminate stress cracking.

The properties of polyethylene are shown in Table 1 - 1.

Property | Low - density | Medium - density | High - density (Melt flow rate > 1 g/(10 min)) | High - density |

Melt flow rate>1g/(10min) | Melt flow rate=0 |

Density / (g/cm³) | 0.910 - 0.925 | 0.926 - 0.940 | 0.941 - 0.965 | 0.945 |

Average relative molecular mass | ≈3×10⁵ | ≈2×10⁵ | ≈1.25×10⁵ | (1.5 - 2.5)×10⁶ |

Refractive index (%) | 1.51 | 1.52 | 1.54 | - |

Gas permeability rate (relative value) | 1 | 1 1/3 | 1/3 | - |

Elongation at break (%) | 90 - 800 | 50 - 600 | 15 - 100 | - |

Shore hardness (Hₐ) | 41 - 50 | 50 - 60 | 60 - 70 | 55 (Rockwell hardness HRR) |

Impact strength (cantilever beam, notched) / (J/m²) | >853.4 | >853.4 | 80 - 1067 | >1067 |

Tensile strength / MPa | 6.9 - 15.9 | 8.3 - 24.1 | 21.4 - 37.9 | 37.2 |

Tensile elastic modulus / MPa | 117.2 - 241.3 | 172.3 - 379.2 | 413.7 - 1034 | 689.5 |

Continuous heat - resistant temperature / °C | 82 - 100 | 104 - 121 | 121 | - |

Heat distortion temperature (0.46 MPa) / °C | 38 - 49 | 49 - 74 | 60 - 82 | 73 |

Specific heat capacity / [J/(kg·K)] | 2302.7 | - | 2302.7 | - |

Crystallization melting point / °C | 108 - 126 | 126 - 135 | 126 - 136 | 135 |

Brittleness temperature / °C | - 80 - - 55 | - | < - 140 - - 100 | < - 137 |

Melt flow rate / [g/(10 min)] | 0.2 - 30 | 0.1 - 4.0 | 0.1 - 4.0 | 0.00 |

Linear expansion coefficient / K⁻¹ | (16 - 18)×10⁻⁵ | (14 - 16)×10⁻⁵ | (11 - 13)×10⁻⁵ | 7.2×10⁻⁵ |

Thermal conductivity / [W/(m·K)] | 0.35 | - | 0.46 - 0.52 | - |

Arc resistance / s | 135 - 160 | 200 - 235 | - | - |

Relative dielectric constant | 60 - 100Hz | 2.25 - 2.35 | 2.25 - 2.35 | 2.30 - 2.35 | 2.34 |

1MHz | 2.25 - 2.35 | 2.25 - 2.35 | 2.30 - 2.35 | 2.30 |

Dielectric loss factor | 60 - 100Hz | <5×10⁻⁴ | <5×10⁻⁴ | <5×10⁻⁴ | <3×10⁻⁴ |

1MHz | <5×10⁻⁴ | <5×10⁻⁴ | <5×10⁻⁴ | <2×10⁻⁴ |

Volume resistivity (RH50%, 23°C) / (Ω·cm) | >10¹⁶ | >10¹⁶ | >10¹⁶ | >10¹⁶ |

Dielectric strength / (kV/mm) | Short - time | 18.4 - 28.0 | 20 - 28 | 18 - 20 | 28.4 |

Step - by - step | 16.8 - 28.0 | 20 - 28 | 17.6 - 24 | 27.2 |

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk