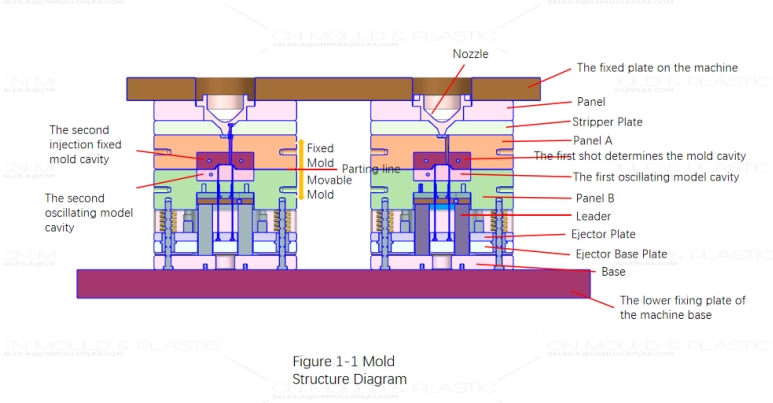

Figure 1-1 shows the mold structure diagram of this two-color product. On the right side of the figure is the molding diagram of the first-color product, and on the left side is the molding diagram of the second-color product.

The mold base of this mold adopts LMK brand. The fixed mold cavity is made of P20 material with a hardness of 35-38HRC; the moving mold core is made of P20 material with a hardness of 35-38HRC; the inserts are also made of P20 material with a hardness of 35-38HRC; the slider is made of 1.2344 material, and the heat treatment technical requirements are: the hardness after quenching and tempering is 48-50HRC; the straight ejector is made of SKD61 material, and the heat treatment technical requirements are: the hardness after quenching and tempering is 40-44HRC, and the hardness after surface nitriding treatment is 1000-1080HV; the push block is made of P20 material, and the heat treatment technical requirements are: the surface nitriding treatment hardness is 650-700HV; other standard parts adopt HASCO brand standard parts.

This set of molds is produced on a DY vertical two-color injection molding machine. Figure 1-2 shows the overall view of the mold.

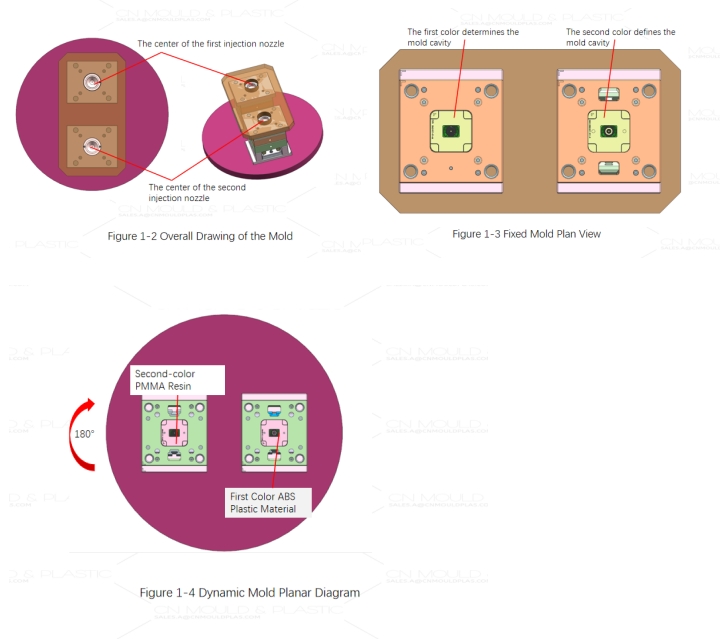

Figure 1-3 and Figure 1-4 show the fixed mold plan and the moving mold plan respectively. After the mold is installed, the injection molding machine first clamps for the first time. After completing the injection molding of the first-color product, the injection molding machine opens the mold for the first time. When the fixed mold and the moving mold are completely separated, the turntable on the moving mold side rotates 180°, and the injection molding machine clamps for the second time to complete the injection molding of the second-color product. After that, the injection molding machine opens the mold again. When the mold is completely opened, the product is ejected by the rear mold ejection rod on the second-color mold side, completing the injection molding of the complete two-color product.

In actual injection molding production, in each injection molding cycle, the first-color product and the second-color product of the injection molding machine are simultaneously injection-molded to produce one first-color product and one complete two-color product. After each mold opening, the ejection rod of the second-color mold of the injection molding machine drives the ejector plate, ejector support plate, ejector pins, straight ejectors, and push blocks in the mold. After ejecting the second-color product and the cold runner, the moving mold worktable rotates to drive the moving mold to the next working position, and the injection molding machine clamps to continue injection molding, so as to produce continuously.

Notes:

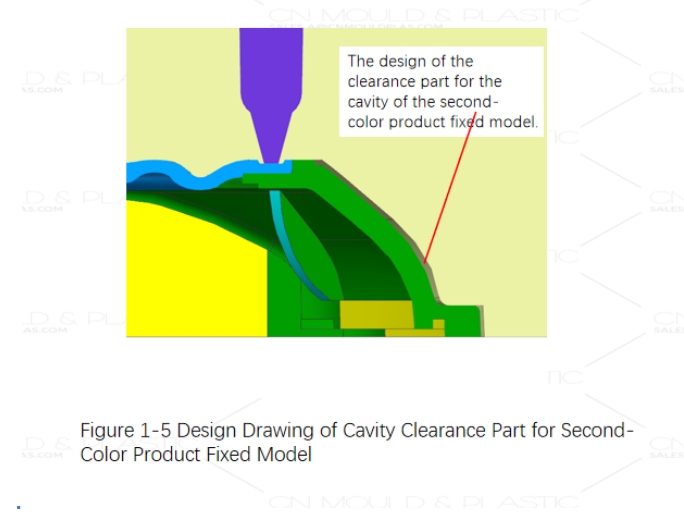

When designing the cavity for the second-color molding, it is necessary to design a venting part for the positions where the first-color product is not sealed. This can prevent the first-color product from being crushed and reduce the processing difficulty of the mold, as shown in Figure 1-5.