The dimensions of the product (Figure 1-1) are 52mm x 165mm x 198mm. The green section is molded from the first-color ABS compound, while the orange section uses the second-color PMMA compound (transparent). Both materials are rigid plastics. With a relatively simple structure and medium size, this represents a basic two-shot molding product. The mold design specifies a 1+1 cavity configuration (one cavity for each material).

The parting line of this product is relatively straightforward and can follow the maximum contour of the first-shot ABS material, as shown in Figures 2-2 and 2-3.

Given the simple structure of this product, there are no undercuts on either the stationary or moving mold halves. However, a detailed analysis of the second-shot material reveals that it cannot be fully contained within the moving mold cavity, as illustrated in Figure 2-4. This indicates that the product does not meet the fundamental principle of simple dual-color mold design: the stationary mold should have different geometries for each shot, while the moving mold must remain identical.

To address this, a split-core design is proposed for the central hole feature of the second-shot component. Specifically:

· Parting Strategy: The hole will be split equally between the stationary and moving molds.

· Core Pull Mechanism: A retractable core will be incorporated into the moving mold to facilitate the formation of both the first and second-shot components.

This solution ensures successful molding of both material layers, as shown in Figure 2-5.

Before setting the gate position, it is essential to first analyze in detail how the mold will function:

Figure 2-6 illustrates the positions of the moving mold sliding inserts, moving mold slides, and fixed mold angle pins during the injection of the first-color ABS material.

At this point, under the action of the inclined pressing block on the fixed mold, the sliding molding insert of the movable mold is brought into contact with the fixed mold through the sliding block of the movable mold to prevent the first-color rubber material from flowing into the position of the sliding molding insert of the movable mold, as shown in the enlarged view at position A in Figure 2-7.

After the first-color rubber material is injected and molded, the injection molding machine performs the first mold opening. During this process, the moving mold slide and the moving mold sliding insert remain stationary under the action of the positioning ball plungers.

Once the first mold opening is completed, the moving mold turntable rotates the moving mold assembly by 180°, followed by the second mold closing to inject the second-color PMMA material. The state of the inner slide mechanism at this stage is shown in Figure 2-8.

During the second mold closing:

1. The angled pressure block on the stationary mold of the second-color cavity acts on the moving mold slide.

2. This action drives the moving mold sliding insert and the stationary mold component to retreat to the position required for the second-color PMMA molding (see the enlarged view at Section B in Figure 2-9).

Key Design Principle:

By strategically positioning different angled pressure blocks on the stationary molds, the same moving mold slide mechanism is controlled to achieve precise positioning changes of the sliding insert between the first-color and second-color molding processes.

Advantages:

· Simplified mold structure reduces manufacturing costs.

· Enhanced stability of mold movements during multi-color injection cycles.

After finalizing the mold structure, the gating system for this two-color product was analyzed. To meet the cosmetic requirements, both the first-shot ABS material and the second-shot PMMA material ,submarine gating via hot runner system. The gate locations are strategically placed on non-visible areas of the product, as shown in Figures 2-10 and 2-11.

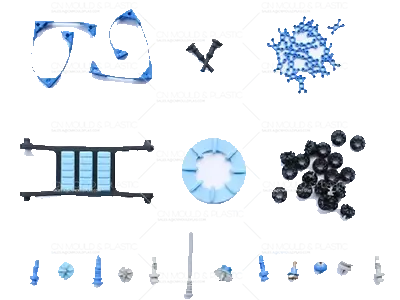

After the first-shot ABS injection, the moving platen rotates 180°, followed by the second-shot PMMA injection. Once both shots are completed, the ejection system at the second-shot cavity utilizes a combination of ejector blocks, ejector pins, and straight lifters, as illustrated in Figure 2-12.