Case description

Customer background

Industry: Automobile manufacturing

Demand: Development of new two-color injection molded parts to improve product performance and market competitiveness and reduce production costs.

Challenges and needs

Problems facing :

Customers need to improve the sealing performance and durability of existing products to meet increasingly stringent automotive safety and environmental requirements.

Technology upgrades need to be implemented quickly on existing production lines to minimize production disruptions and reduce conversion costs.

Pursue higher precision and consistency of injection molded parts to reduce scrap rates and customer complaints.

Pain points :

The existing injection molding process cannot meet the new sealing performance standards.

Production line adjustment is complex, involving the coordination of multiple sets of molds and equipment.

The quality inspection means are insufficient, it is difficult to completely eliminate defective products

Solution

Technology or services provided :

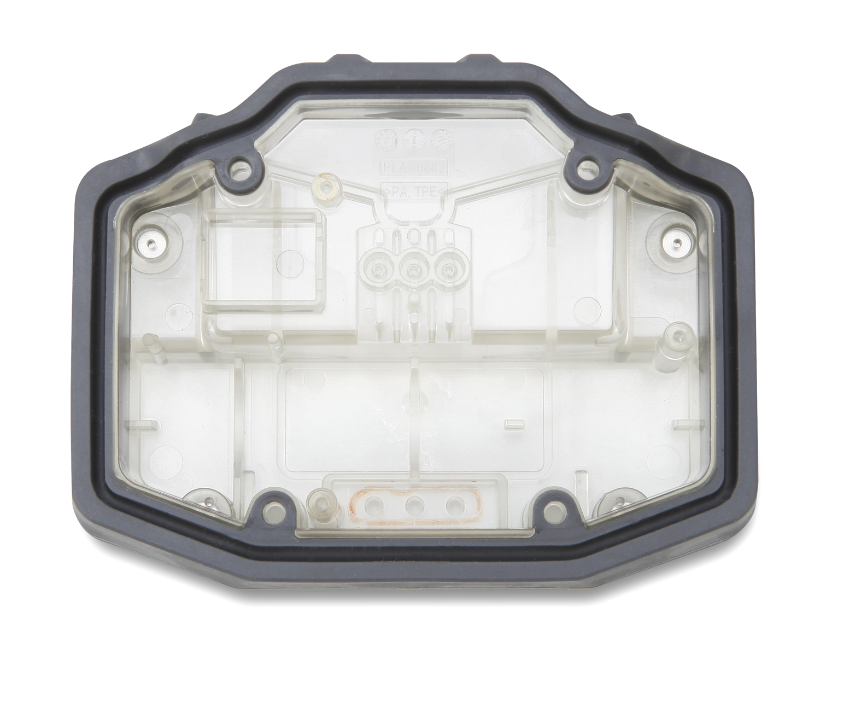

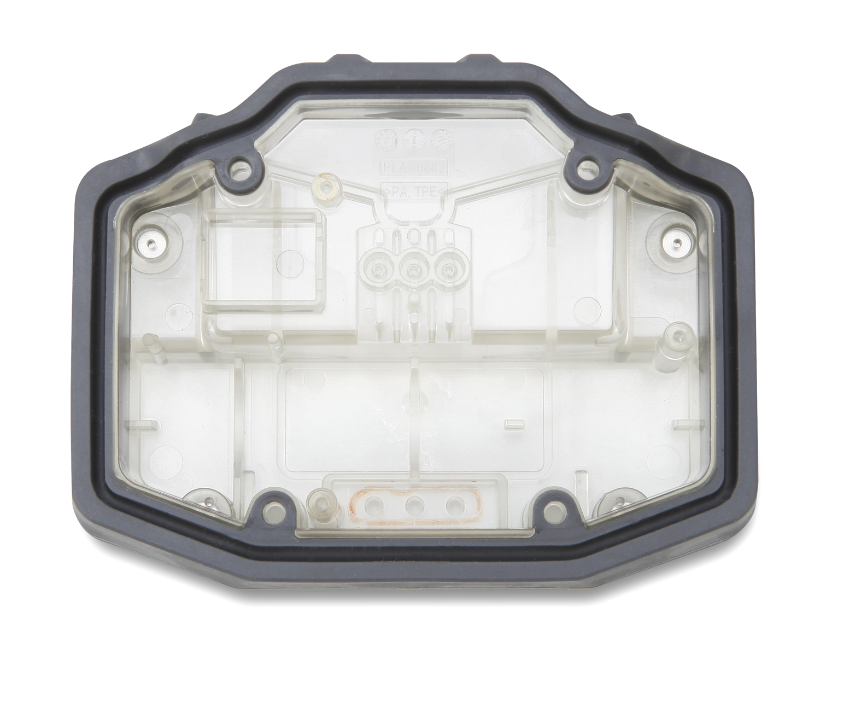

Two-color injection molding: By introducing an advanced two-color injection molding process, we provide customers with transparent and durable parts designed to meet the dual requirements of tightness and strength of automotive parts.

Mold design and manufacturing: Customized development of high-precision molds to ensure the consistency and detail accuracy of injection parts, so as to improve product quality and reduce reject rate.

Line optimization: Through engineering analysis and simulation, we make optimization suggestions on customers' production lines to ensure rapid upgrade and efficient operation, with reduced production disruptions and costs.

Material selection: According to the application requirements, select the appropriate two-color injection molding material combination, to provide the whole process support from concept to mass production.

Unique advantages :

Improve product tightness and durability to meet industry safety standards.

Precision mold design and rapid production line upgrade to ensure high efficiency and low consumption.

Consistency and high precision of two-color injection molded parts to reduce the scrap rate.

Project results :

By introducing two-color injection molding technology, the sealing performance and durability of automotive parts have been significantly improved, and customer complaints have been reduced.

The adjustment time of the production line has been shortened, the production cost has been reduced, and the production efficiency has been improved.

The scrap rate has decreased, significantly reducing resource waste.

We have successfully solved the manufacturing and material compatibility issues of complex components for our clients, significantly enhancing the manufacturing quality and efficiency of the components. The client highly recognized our technology and services, praised our professionalism and flexibility in technology, and looked forward to cooperating on more projects.

Customer comments :

Through close cooperation with our professional team, we have successfully applied two-color injection molding technology to production, significantly improving product quality and competitiveness. After the optimization of the production line, efficiency was significantly improved, costs were effectively controlled, and we are very pleased with the results.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk