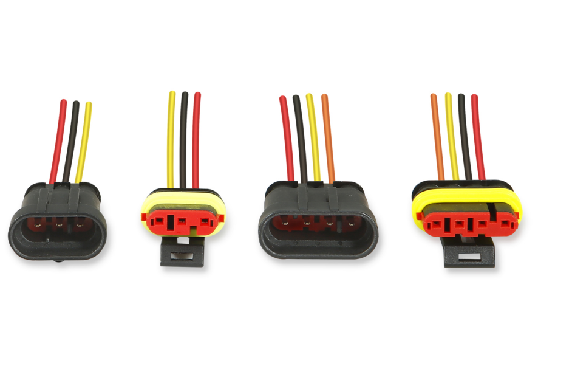

The customer needs to optimize the rubber overmolding process of automotive wiring harnesses to address issues such as insufficient wear resistance and unstable insulation performance of existing materials, in order to meet the reliability challenges of automotive electrical systems under complex working conditions

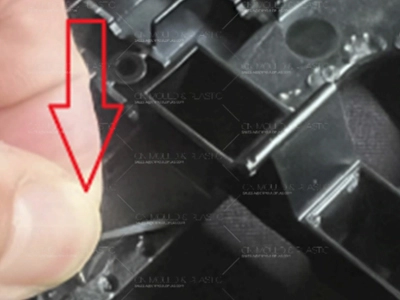

The wire harness is prone to wear: the original overmolding material has insufficient anti-aging performance, causing the wire harness to crack easily in vibration and high temperature environments, the repair rate is high.

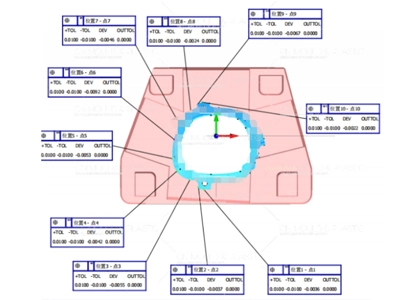

Poor consistency of process : The manual overmolding process causes uneven thickness, affecting insulation performance and posing safety hazards.

Cost pressure: Frequent rework and material waste are driving up production costs, and customers urgently need solutions that balance performance and cost-effectiveness.

Customized wire harness overmolding material :

With a high-performance polymer substrate , abrasion resistance is enhanced (laboratory tests show a 50% increase in abrasion resistance) and aging resistance (no cracking at -40 ° C to 150 ° C).

Optimize the material formula to enhance the adhesion to wire harness substrates such as PVC and PA66+33GF

Automated the overmolding process :

Eliminate manual operation deviation.

Integrate an online quality inspection system to monitor insulation performance in real time.

Quality improvement: Harness return rate has been significantly reduced, and product life has been extended.

Efficiency optimization : Automated processes have effectively improved production efficiency and increased daily capacity.

Cost savings: Reduced overall production cost

“CN team's wire harness overmolding process has completely transformed our production pain points!

Real-time monitoring of curing temperature and overmolding uniformity to ensure stable yield, which is far exceeding the industry average.

The precision of your craftsmanship and your fast response capability are the core reasons why we chose a long-term partnership ."