Industry: Electronic equipment manufacturing

Requirements: Customers need to develop a high-precision, high-reliability pin injection solution for their electronic devices to improve product stability and durability.

1. The pin is easily displaced or damaged during injection molding, resulting in a decrease in product yield.

2. A process is required that ensures the pin is tightly attached to the injection molded part to prevent loosening and poor contact.

3. The coefficient of thermal expansion of the pin is different from that of the injection material, which may lead to stress concentration and pin fracture.

1. Improve pin stability and durability during injection molding.

2. Ensure that the pins and injection parts are tightly integrated to improve product reliability.

3. Reduce production waste and cost increases due to pin damage.

Our company provides customers with an innovative pin insert molding technology. Specific solutions are as follows:

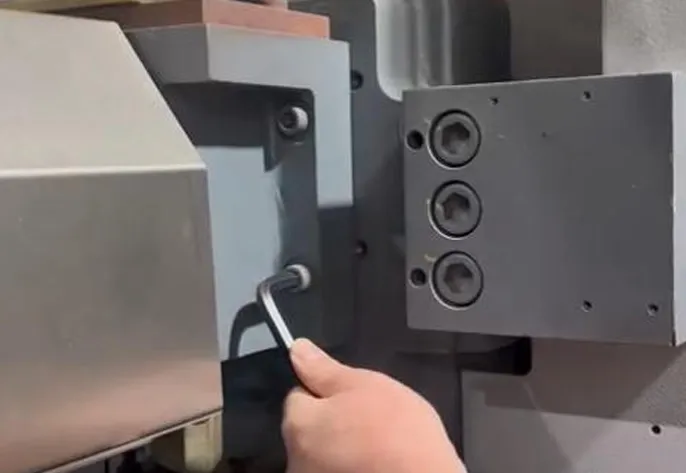

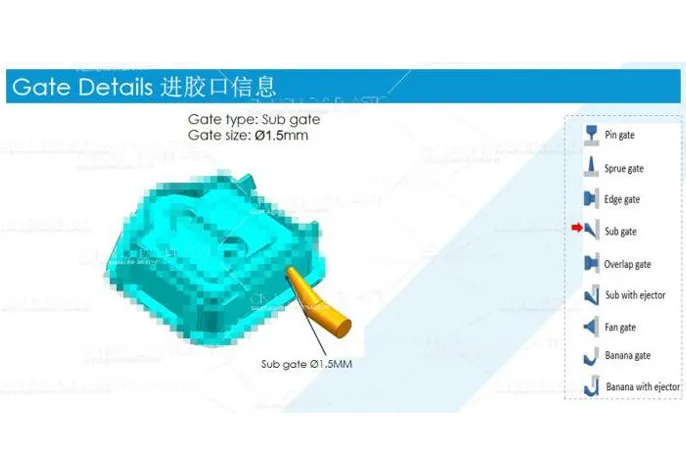

1. High-precision mold design : The use of high-precision mold design ensures that the pin in the injection process remains fixed, preventing displacement and damage.

2. Pin insert molding process : Through the pin insert molding process, the insert pin is closely combined with the plastic molding material to form a solid whole to prevent loosening and poor contact.

3. Material selection and optimization : Select the pin and injection material with a similar thermal expansion coefficient to reduce stress concentration and prevent pin breakage.

4. Quality monitoring and testing : Through the strict quality monitoring and testing process, to ensure that every product is in line with customer requirements.

After the implementation of the project, the customer feedback is as follows:

1. The product yield was significantly improved.

2. Production costs are reduced, and waste due to pin damage is reduced.

3. Product stability and durability are greatly improved, and customer satisfaction is extremely high.

"Thank you for providing us with the pin insert molding solution, which not only greatly improves our product yield, but also significantly reduces the production cost. CN team's technology and services are very professional and trustworthy."

Through the above cases, our company successfully demonstrated its professional ability in the field of pin insert molding and won the trust and praise of customers.